Use of nonlinear loads such as power electronics based equipment and electric furnaces have been on the rise for the last decades. Such loads decrease the power quality of the network that they are connected to. One of the most important parameters for defining the power quality is harmonic distortion.

Harmonic distortion in a network causes:

- Equipment over-heating

- Insulation failure due to overheating and higher voltage peaks than rated fundamental voltage (50Hz or 60Hz) sinusoidal signal

- Equipment malfunction (false zero cross detection on power electronics devices)

- Communication interference

- Increased noise in electrical machines

- Fuse and breaker mis-operation

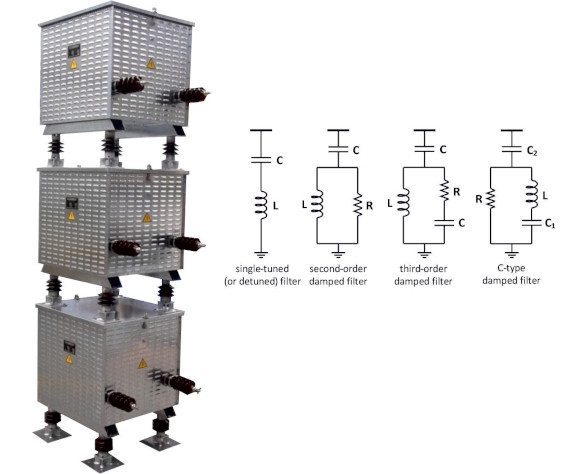

Passive harmonic filters are the most commonly used devices for reducing the harmonic distortion in a network. These filters are built up from passive RLC components, i.e. resistors, inductors and capacitors.

The inductors (reactors) in these filters serve to provide a resonance path together with the capacitors existing in the harmonic filter. By appropriately tuning the resonance frequency of a harmonic filter, the unwanted harmonic currents injected by the nonlinear loads can be prevented from going into the electrical grid. This is a very important measure that is taken for reducing the harmonic distortion in a network. Harmonic filter reactors may be used in single-tuned, second order, and C-type filters according to the type of load and purpose. Moreover, they may be used in series with Flexible AC Transmission Systems (FACTS) devices such as Static VAr Compensator (SVC), Static Synchronous Compensator (STATCOM) and High Voltage Direct Transmission (HVDC) in order to reduce the amount of harmonics that would be injected by these systems into the electrical grid.

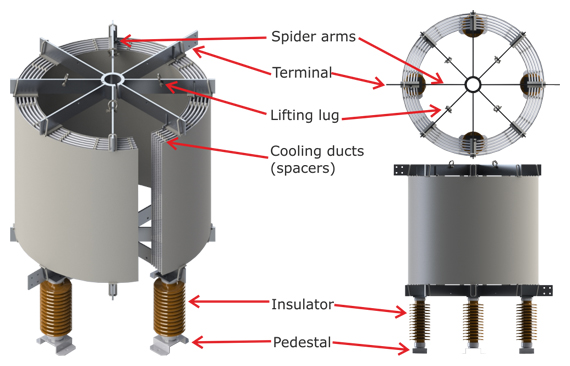

At medium voltage level, usually air core dry type reactors are used as harmonic filter reactors. Having no magnetic core, air core reactors are free from saturation. They may be installed outdoor and indoor as long as magnetic flux path is considered during installation in order to stay away from ferromagnetic material during use.

In some industrial applications such as arc furnaces and ladle melt furnaces, it is vital to filter out some harmonics while not amplifying the existing interharmonics. Otherwise, excessive heating or overvoltages can occur which may damage or at least degrade the lifetime of equipment. Moreover, industrial customers are forced to obey harmonic current and harmonic voltage limits defined with respect to voltage level and with respect to the ratio of short circuit power to load power, in standards such as IEEE 519.92. Therefore, careful design of the tuning frequency and rating of the reactors is important and must consider a wide frequency band including both the harmonics and interharmonics.

All Hilkar air core harmonic filter reactors are custom designed for various and diverse applications. The designs take into consideration the voltage, current, inductance, type of application (or filter type), harmonics, interharmonics, size, transient events such as switchings and loss characteristics in order to provide the most efficient design at the most economical prices. All the routine tests are performed in accordance with EN 60289 or other standards depending on customer request. Type test reports are available on request. All the test reports are submitted to customer. Basic testing program includes some or all of the following tests:

- Routine Tests (Inductance, Resistance, One Minute AC Insulation Voltage Withstand Test and Impulse Voltage Withstand Test)

- Short Circuit Withstand Test

- Temperature Rise Test

- Sound Level Test

- Seismic Test